Springs and elastic elements springs and elastic. The spring pitch is determined by the dependence Questions for self-examination

The elastic properties of the spring suspension are evaluated using the power characteristics and the stiffness coefficient or the coefficient of flexibility (flexibility). In addition, springs and springs are characterized by geometric dimensions. The main dimensions (Fig. 1) include: the height of the spring or spring in a free state without load H s and the height under load H gr, the length of the spring, the diameter of the spring, the diameter of the rod, the number of working coils of the spring. The difference between H sv and H gr is called spring deflection (springs)f. The deflection obtained from a load lying quietly on the spring is called static. For leaf springs, for more convenient measurement, the deflection is determined by the dimensions H St and H gr near the clamp. Flexible properties of springs (springs) determined by one of two quantities:

- flexibility factor(or just flexibility);

- stiffness coefficient(or just hardness).

Rice. 1 - Main dimensions of springs and springs

The deflection of a spring (spring) under the action of a force equal to unity is called flexibility f 0:

where P is the external force acting on the spring, N;

f - spring deflection, m.

An important characteristic of a spring is its rigidity. and, which is numerically equal to the force that causes deflection equal to one. Thus,

and= P/f.

For springs whose deflection is proportional to the load, the equality

P= and f.

Rigidity- the reciprocal of flexibility. Flexibility and stiffness of springs (springs) depend on their main dimensions. With an increase in the length of the spring or with a decrease in the number and cross-section of sheets, its flexibility increases, and its rigidity decreases. For springs, with an increase in the average diameter of the turns and their number, and with a decrease in the cross section of the rod, the flexibility increases, and the rigidity decreases.

The magnitude of the stiffness and deflection of the spring or spring is determined linear dependence between its deflection and the elastic force P = and f, presented graphically in (Fig. 2). The diagram of the operation of a frictionless cylindrical spring (Fig. 2, a) is depicted by one straight line 0A, corresponding to both the loading of the spring (an increase in P) and its unloading (a decrease in P). Rigidity in this case is a constant value:

and= P/f∙tgα.

Springs of variable stiffness (aperiodic) without friction have a diagram in the form of a line 0AB (Fig. 2, b).

Rice. 2 - Diagrams of the operation of springs (a, b) and springs (c)

At leaf spring operation friction occurs between its sheets, which contributes to the damping of the vibrations of the sprung vehicle and creates a more relaxed movement. At the same time, too much friction, increasing the stiffness of the spring, degrades the suspension quality. The nature of the change in the elastic force of the spring under static loading is shown in (Fig. 2, c). This relationship is a closed curved line, the upper branch of which 0A 1 shows the relationship between the load and deflection of the spring when it is loaded, and the lower A 1 A 2 0 - when unloaded. The difference between the branches characterizing the change in the elastic forces of the spring when it is loaded and unloaded is due to friction forces. The area bounded by the branches is equal to the work expended on overcoming the friction forces between the leaf springs. When loaded, the friction forces seem to resist the increase in deflection, and when unloaded, they prevent the spring from straightening. In wagon springs, the friction force increases in proportion to the deflection, since the forces of pressing the sheets against each other increase accordingly. The amount of friction in the spring is usually estimated by the so-called coefficient of relative friction φ, equal to the ratio of the friction force Rtr to the force P that creates the elastic deformation of the spring:

The magnitude of the friction force is related to the deflection f and the stiffness of the spring and, due to its elastic properties, dependence

ELASTIC ELEMENTS. SPRINGS

Wheel pairs of wagons are connected to the bogie frame and wagon body through a system of elastic elements and vibration dampers, called spring suspension. Spring suspension due to elastic elements provides mitigation of shocks and shocks transmitted by the wheels to the body, as well as due to the dampers, damping vibrations that occur during the movement of the car. In addition (in some cases), springs and springs transmit the guiding forces from the side of the wheels to the frame of the wagon bogie.

When a wheel pair passes any road roughness (joints, crosses, etc.), dynamic loads occur, including shock loads. The appearance of dynamic loads is also facilitated by defects in the wheelset - local defects in the tread surfaces, eccentricity of the wheel on the axle, unbalance of the wheelset, etc. In the absence of spring suspension, the body would rigidly perceive all dynamic effects and experience large accelerations.

The elastic elements located between the wheel pairs and the body, under the influence of a dynamic force from the side of the wheel pair, deform and oscillate together with the body, and the period of such oscillations is many times longer than the period of change of the perturbing force. As a result, accelerations and forces perceived by the body are reduced.

We will consider the softening effect of spring suspension during the transmission of shocks to the body using the example of the movement of a car along a rail track. When the wagon wheel rolls along the track, due to the unevenness of the rail and defects in the rolling surface of the wheel, the wagon body, when it is connected without springs to the wheel pairs, will copy the trajectory of the wheel (Fig. A). The trajectory of the car body (line a1-b1-c1) coincides with the roughness of the track ( line a-b-c). In the presence of spring suspension, vertical shocks (Fig. b) are transmitted to the body through elastic elements, which, softening and partially absorbing shocks, provide a calmer and smoother running of the car, protect the rolling stock and the track from premature wear and damage. In this case, the trajectory of the body movement can be depicted by the line a1-b2-c2, which has a flatter appearance compared to the line a to c. As can be seen from fig. b, the period of oscillation of the body on the springs is many times greater than the period of change of the disturbing force. As a result, accelerations and forces perceived by the body are reduced.

Springs are widely used in car building, in bogies of freight and passenger cars, in shock-traction devices. Distinguish between coil springs and spiral springs. Helical springs are made by coiling steel bars of round, square or rectangular cross section. Coil springs come in cylindrical and conical shapes.

Varieties of helical springs

a - cylindrical with a rectangular section of the rod; b - cylindrical rod with a round section; in - conical with a round section of the rod; g - conical with a rectangular section of the rod

In the spring suspension of modern cars, coil springs are most widely used. They are easy to manufacture, reliable in operation and well absorb vertical and horizontal shocks and impacts. However, they cannot dampen vibrations of the wagon's sprung masses and are therefore only used in combination with vibration dampers.

Springs are made in accordance with GOST 14959. The supporting surfaces of the springs are made flat and perpendicular to the axis. To do this, the ends of the spring blank are pulled back by 1/3 of the circumference of the coil. As a result, a smooth transition from a round to a rectangular section is achieved. The height of the drawn end of the spring should be no more than 1/3 of the bar diameter d, and the width should be at least 0.7d.

The characteristics of a cylindrical spring are: the diameter of the rod d, the average diameter of the spring D, the height of the spring in the free Hsv and compressed Hszh states, the number of working turns np and the index m. The spring index is the ratio of the average spring diameter to the diameter of the rod, i.e. t = D/d.

Cylindrical spring and its parameters

Material for springs and leaf springs

The material for springs and springs must have high static, dynamic, impact strength, sufficient ductility and retain its elasticity throughout the life of the spring or spring. All these properties of the material depend on its chemical composition, structure, heat treatment and the state of the surface of the elastic element. Springs and springs for wagons are made of steel 55S2, 55S2A, 60S2, 60S2A (GOST 14959–79). Chemical composition steel percentage: C = 0.52 - 0.65; Mn = 0.6 - 0.9; Si = 1.5 - 2.0; S, P, Ni not more than 0.04 each; Cr not more than 0.03. Mechanical properties of heat-treated steels 55S2 and 60S2: ultimate strength of 1300 MPa with a relative elongation of 6 and 5% and a narrowing of the cross-sectional area of 30 and 25%, respectively.

In the manufacture of springs and springs are subjected to heat treatment - hardening and tempering.

The strength and wear resistance of springs and springs to a greater extent depends on the state of the metal surface. Any damage to the surface (small cracks, captivity, sunsets, dents, risks and similar defects) contributes to the concentration of stresses under loads and sharply reduces the endurance limit of the material. For surface hardening, factories use shot blasting of leaf springs and springs.

The essence of this method lies in the fact that the elastic elements are exposed to the action of a stream of metal shot with a diameter of 0.6–1 mm, ejected at a high speed of 60–80 m/s onto the surface of the spring leaf or spring. The speed of the shot is selected so that at the point of impact a stress is created above the elastic limit, and this causes plastic deformation (hardening) in the surface layer of the metal, which ultimately strengthens the surface layer of the elastic element.

In addition to shot blasting, hardening of springs can be done by hardening, which consists in keeping the springs in a deformed state for a certain time. The spring is coiled in such a way that the distances between the coils in the free state are made a certain amount larger than according to the drawing. After heat treatment, the spring is removed until the coils touch and kept in this state from 20 to 48 hours, then it is heated. During compression, residual stresses of the opposite sign are created in the outer zone of the cross section of the rod, as a result of which, during its operation, the true stresses turn out to be less than they would be without captivity.

In the photo - new coil springs

Hot spring winding

Checking the elasticity of the spring

Cylindrical springs, depending on the load perceived by them, are made single-row or multi-row. Multi-row springs consist of two, three or more springs nested one inside the other. In double-row, the outer spring is made from a bar of larger diameter, but with a small number of turns, the inner spring is made from a bar of smaller diameter and with a large number of turns. In order for the coils of the inner spring not to be clamped between the coils of the outer spring during compression, both springs are twisted in different directions. In multi-row springs, the dimensions of the bars also decrease from the outer spring to the inner one, and the number of coils increases accordingly.

Multi-row springs allow, with the same dimensions as a single-row spring, to have greater rigidity. Two-row and three-row springs are widely used in bogies of freight and passenger cars, as well as draft gears of automatic couplers. Power characteristic multi-row springs is linear.

In some designs of double-row springs (for example, in bogies 18-578, 18-194), the outer springs of the spring set are higher than the inner ones, due to which the suspension rigidity of an empty car is 3 times less than that of a loaded car.

Springs installed on the wagon

They are formed by protrusions on the shaft, which are included in the mating grooves of the wheel hub. What is it in appearance, and according to the dynamic conditions of operation, splines can be considered multi-key connections. Some authors call them serrations.

Basically, straight-sided splines are used (a), involute (b) GOST 6033-57 and triangular (c) spline profiles are less common.

Basically, straight-sided splines are used (a), involute (b) GOST 6033-57 and triangular (c) spline profiles are less common.

Straight-sided splines can center the wheel along the side surfaces (a), along the outer surfaces (b), along the inner surfaces (c).

Compared to splines, splines:

Have a large bearing capacity;

Better center the wheel on the shaft;

Strengthen the shaft section due to the greater moment of inertia of the ribbed section compared to the round one;

` require special equipment for making holes.

The main criteria for the performance of slots are:

è resistance of side surfaces to crushing (calculation is similar to dowels);

è wear resistance during fretting corrosion (small mutual vibrational movements).

Crushing and wear are associated with one parameter - contact stress (pressure) s cm . This allows splines to be calculated according to the generalized criterion for both crushing and contact wear. Permissible stresses [ s]cm assigned on the basis of operating experience of similar structures.

For the calculation, the uneven distribution of the load over the teeth is taken into account,

Where Z - number of slots h – working height of slots, l - working length of the slots, d cf - the average diameter of the spline connection. For involute splines, the working height is taken equal to the modulus profile, for d cf take the pitch diameter.

Conventions straight-sided spline connection is made up of the designation of the centering surface D , d or b , number of teeth Z , nominal sizes d x D (as well as the designation of tolerance fields for the centering diameter and on the sides of the teeth). For example, D 8 x 36H7/g6 x 40 means eight-spline connection centered on the outer diameter with dimensions d = 36 And D =40 mm and fit on the centering diameter H7/g6 .

CONTROL QUESTIONS

s What is the difference between detachable and non-detachable connections?

s Where and when are welded joints used?

s What are the advantages and disadvantages of welded joints?

s What are the main groups of welded joints?

s How do the main types of welds differ?

s What are the advantages and disadvantages of riveted joints?

s Where and when are riveted joints used?

s What are the criteria for strength analysis of rivets?

s What is the design principle of threaded connections?

s What are the applications for the main thread types?

s What are the advantages and disadvantages of threaded connections?

s Why is it necessary to lock threaded connections?

s What designs are used to lock threaded connections?

s How is the ductility of parts taken into account when calculating a threaded connection?

s What thread diameter is found from the strength calculation?

s What is the thread diameter to indicate the thread?

s What is the design and main purpose of pin connections?

s What are the load types and design criteria for pins?

s What is the design and main purpose of keyed joints?

s What are the load types and design criteria for keys?

s What is the design and main purpose of splines?

What are the types of loading and criteria for calculating splines

SPRINGS. ELASTIC ELEMENTS IN MACHINES

Each car has specific details that are fundamentally different from all the others. They are called elastic elements. Elastic elements have a variety of designs that are very different from each other. Therefore, a general definition can be given.

Elastic elements are parts whose rigidity is much less than the rest, and the deformations are higher.

Due to this property, elastic elements are the first to perceive shocks, vibrations, and deformations.

Most often, elastic elements are easy to detect when inspecting a machine, such as rubber tires wheels, springs and springs, soft seats for drivers and drivers.

Sometimes the elastic element is hidden under the guise of another part, for example, a thin torsion shaft, a stud with a long thin neck, a thin-walled rod, a gasket, a shell, etc. However, here, too, an experienced designer will be able to recognize and use such a "disguised" elastic element precisely by its relatively low rigidity.

On railway due to the severity of the transport, the deformation of the track parts is quite large. Here, the elastic elements, along with the springs of the rolling stock, actually become rails, sleepers (especially wooden, not concrete) and the soil of the track embankment.

Elastic elements are widely used:

è for shock absorption (reduction of accelerations and inertial forces during shocks and vibrations due to the significantly longer deformation time of the elastic element compared to rigid parts);

è to create constant forces (for example, elastic and split washers under the nut create a constant friction force in the threads, which prevents self-unscrewing);

è for forceful closing of mechanisms (to eliminate unwanted gaps);

è for the accumulation (accumulation) of mechanical energy (clock springs, the spring of a weapon striker, the arc of a bow, the rubber of a slingshot, a ruler bent near a student's forehead, etc.);

è for measuring forces (spring balances are based on the relationship between weight and strain of the measuring spring according to Hooke's law).

Typically, elastic elements are made in the form of springs of various designs.

The main distribution in machines are elastic compression and extension springs. In these springs, the coils are subject to torsion. The cylindrical shape of the springs is convenient for placing them in machines.

The main characteristic of a spring, like any elastic element, is stiffness or its inverse compliance. Rigidity K determined by the dependence of the elastic force F from deformation x . If this dependence can be considered linear, as in Hooke's law, then the stiffness is found by dividing the force by the deformation K =f/x .

If the dependence is non-linear, as is the case in real structures, the stiffness is found as the derivative of the force with respect to deformation K =∂ F/ ∂ x.

Obviously, here you need to know the type of function F =f (x ) .

For large loads, if it is necessary to dissipate the energy of vibration and shock, packages of elastic elements (springs) are used.

The idea is that when the composite or layered springs (springs) are deformed, the energy is dissipated due to the mutual friction of the elements.

A package of disc springs is used to absorb shocks and vibrations in the inter-bogie elastic coupling of electric locomotives ChS4 and ChS4 T.

In the development of this idea, at the initiative of the employees of our academy, on the Kuibyshev Road, disk springs (washers) are used in bolted joints of rail joint linings. The springs are placed under the nuts before tightening and provide high constant friction forces in the connection, besides unloading the bolts.

Materials for elastic elements should have high elastic properties, and most importantly, not lose them over time.

The main materials for springs are high-carbon steels 65.70, manganese steels 65G, silicon steels 60S2A, chrome-vanadium steel 50HFA, etc. All of these materials have superior mechanical properties compared to conventional structural steels.

In 1967, at the Samara Aerospace University, a material was invented and patented, called metal rubber "MR". The material is made from crumpled, tangled metal wire, which is then pressed into the required shapes.

The colossal advantage of metal rubber is that it perfectly combines the strength of metal with the elasticity of rubber and, in addition, due to significant interwire friction, it dissipates (dampers) vibration energy, being a highly effective means of vibration protection.

The density of the tangled wire and the pressing force can be adjusted, obtaining the specified values of the stiffness and damping of the metal rubber in a very wide range.

Metal rubber undoubtedly has a promising future as a material for the manufacture of elastic elements.

Elastic elements require very precise calculations. In particular, they are necessarily counted on rigidity, since this is the main characteristic.

However, the designs of elastic elements are so diverse, and the calculation methods are so complex that it is impossible to bring them in any generalized formula. Especially within the framework of our course, which is over here.

CONTROL QUESTIONS

1. On what basis can elastic elements be found in the design of the machine?

2. For what tasks are elastic elements used?

3. What characteristic of the elastic element is considered the main one?

4. What materials should elastic elements be made of?

5. How to Kuibyshev road Are cup springs used?

| INTRODUCTION………………………………………………………………………………… | |

| 1. GENERAL QUESTIONS OF CALCULATION OF MACHINE PARTS……………………………………... | |

| 1.1. Rows of preferred numbers…………………………………………………... | |

| 1.2. The main criteria for the performance of machine parts…………………… 1.3. Calculation of fatigue resistance at alternating stresses……….. | |

| 1.3.1. Variable voltages……………………………………………….. 1.3.2. Endurance limits……………………………………………….. 1.4. Safety factors……………………………………………………. | |

| 2. MECHANICAL GEARS……………………………………………………………... 2.1. General information……………………………………………………………….. 2.2. Characteristics of drive gears…………………………………………….. | |

| 3. GEARS ………………………………………………………………….. 4.1. Working conditions of the teeth…………………………………………. 4.2. Materials of Gears………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………4.3. Characteristic species destruction of teeth……………………………………… 4.4. Design load……………………………………………………………. 4.4.1. Design load factors…………………………………. 4.4.2. Accuracy of gears…………………………………………….. 4.5. Cylindrical gears……………………………………… | |

| 4.5.1. Forces in engagement………………………………………………………. 4.5.2. Calculation for contact fatigue resistance……………………. 4.5.3. Calculation for bending fatigue resistance……………………… 4.6. Bevel gears……………………………………………… 4.6.1. Main parameters…………………………………………………. 4.6.2. Forces in engagement………………………………………………………. 4.6.3. Calculation for contact fatigue resistance…………………… 4.6.4. Calculation of fatigue resistance in bending……………………. | |

| 5. WORM GEARS…………………………………………………………………. 5.1. General information……………………………………………………………….. 5.2. Forces in engagement………………………………………………………………. 5.3. Materials of worm gears……………………………………………… 5.4. Strength calculation…………………………………………………………….. | |

| 5.5. Thermal calculation…………………………………………………………………. 6. SHAFTS AND AXES………………………………………………………………………………. 6.1. General information……………………………………………………………….. 6.2. Estimated load and performance criterion………………………… 6.3. Design calculation of shafts…………………………………………………. 6.4. Calculation scheme and procedure for calculating the shaft……………………………………….. 6.5. Calculation for static strength………………………………………………. 6.6. Fatigue resistance calculation…………………………………………….. 6.7. Calculation of shafts for stiffness and vibration resistance…………………………… | |

| 7. ROLLING BEARINGS ………………………………………………………………… 7.1. Classification of rolling bearings……………………………………… 7.2. Designation of bearings according to GOST 3189-89……………………………… 7.3. Features of angular contact bearings……………………………… 7.4. Schemes of installation of bearings on shafts……………………………………… 7.5. Estimated load on angular contact bearings………………….. 7.6. Causes of failure and calculation criteria………………………........... 7.7. Materials of bearing parts……..……………………………………. 7.8. Selection of bearings according to static load capacity (GOST 18854-94)………………………………………………………………… | |

| 7.9. Selection of bearings according to dynamic load capacity (GOST 18855-94)……………………………………………………………… 7.9.1. Initial data……………………………………………………. 7.9.2. Basis for selection………………………………………………….. 7.9.3. Features of the selection of bearings……………………………….. | |

| 8. PLAIN BEARINGS…………………………………………………………. | |

| 8.1. General information …………………………………………………………….. | |

| 8.2. Operating conditions and friction modes …………………………………………… | |

| 7. CLUTCHES | |

| 7.1. Rigid Couplings | |

| 7.2. Compensating couplings | |

| 7.3. Movable couplings | |

| 7.4. Flexible couplings | |

| 7.5. Friction clutches | |

| 8. CONNECTIONS OF MACHINE PARTS | |

| 8.1. Permanent connections | |

| 8.1.1. Welded joints | |

| Calculation of the strength of welds | |

| 8.1.2. Rivet connections | |

| 8.2. Detachable connections | |

| 8.2.1. THREADED CONNECTIONS | |

| Calculation of the strength of threaded connections | |

| 8.2.2. Pin connections | |

| 8.2.3. Keyed connections | |

| 8.2.4. Spline connections | |

| 9. Springs…………………………………… |

| | | next lecture ==> | |

SPRINGS AND ELASTIC ELEMENTS n n n 1. general characteristics springs Springs are widely used in constructions as vibration isolating, shock-absorbing, reciprocating, tensioning, dynamometric and other devices. Spring types. According to the type of perceived external load, tension, compression, torsion and bending springs are distinguished.

SPRINGS AND ELASTIC ELEMENTS n n n 1. general characteristics springs Springs are widely used in constructions as vibration isolating, shock-absorbing, reciprocating, tensioning, dynamometric and other devices. Spring types. According to the type of perceived external load, tension, compression, torsion and bending springs are distinguished.

SPRINGS AND ELASTIC ELEMENTS n n twisted springs (cylindrical - extensions, Fig. 1 a, compression, Fig. 1 b; torsion, Fig. 1 c, shaped-compressions, Fig. 1 d-e), special springs (dial-shaped and ring, Fig. 2 a and b, - compression; true and springs, Fig. 2 c, - bending; spiral, Fig. 2 d - torsion, etc.) The most common are twisted cylindrical springs made of round wire.

SPRINGS AND ELASTIC ELEMENTS n n twisted springs (cylindrical - extensions, Fig. 1 a, compression, Fig. 1 b; torsion, Fig. 1 c, shaped-compressions, Fig. 1 d-e), special springs (dial-shaped and ring, Fig. 2 a and b, - compression; true and springs, Fig. 2 c, - bending; spiral, Fig. 2 d - torsion, etc.) The most common are twisted cylindrical springs made of round wire.

SPRINGS AND ELASTIC ELEMENTS n Tension springs (see Fig. 1 a) are wound, as a rule, without gaps between the coils, and in most cases with an initial tension (pressure) between the coils, which partially compensates for the external load. The tension is usually (0.25 - 0.3) Fpr (Fnp is the limiting tensile force at which the elastic properties of the spring material are completely exhausted).

SPRINGS AND ELASTIC ELEMENTS n Tension springs (see Fig. 1 a) are wound, as a rule, without gaps between the coils, and in most cases with an initial tension (pressure) between the coils, which partially compensates for the external load. The tension is usually (0.25 - 0.3) Fpr (Fnp is the limiting tensile force at which the elastic properties of the spring material are completely exhausted).

SPRINGS AND ELASTIC ELEMENTS n n To transfer an external load, such springs are provided with hooks. For example, for springs of small diameter (3-4 mm), the hooks are made in the form of bent last turns (Fig. 3 a-c). However, such hooks reduce the resistance of fatigue springs due to the high concentration of stresses in the places of bending. For critical springs with a diameter of more than 4 mm, embedded hooks are often used (Fig. 3d-e), although they are less technologically advanced.

SPRINGS AND ELASTIC ELEMENTS n n To transfer an external load, such springs are provided with hooks. For example, for springs of small diameter (3-4 mm), the hooks are made in the form of bent last turns (Fig. 3 a-c). However, such hooks reduce the resistance of fatigue springs due to the high concentration of stresses in the places of bending. For critical springs with a diameter of more than 4 mm, embedded hooks are often used (Fig. 3d-e), although they are less technologically advanced.

SPRINGS AND ELASTIC ELEMENTS n n n Compression springs (see Fig. 1 b) are coiled with a gap between the coils, which should be 10-20% higher than the axial elastic displacements of each coil at the highest external load. The support planes of the springs are obtained by pressing the last turns to the neighboring ones and grinding them perpendicular to the axis. Long springs under load can lose stability (bulge). To prevent buckling, such springs are usually placed on special mandrels (Fig. 4 a) or in glasses (Fig. 4 b).

SPRINGS AND ELASTIC ELEMENTS n n n Compression springs (see Fig. 1 b) are coiled with a gap between the coils, which should be 10-20% higher than the axial elastic displacements of each coil at the highest external load. The support planes of the springs are obtained by pressing the last turns to the neighboring ones and grinding them perpendicular to the axis. Long springs under load can lose stability (bulge). To prevent buckling, such springs are usually placed on special mandrels (Fig. 4 a) or in glasses (Fig. 4 b).

SPRINGS AND ELASTIC ELEMENTS n n n Coaxiality of springs with mating parts is achieved by installing support coils in special plates, bores in the body, grooves (see Fig. 4 c). Torsion springs (see Fig. 1 c) are usually wound with a small angle of rise and small gaps between the coils (0.5 mm). They perceive the external load with the help of hooks formed by the bending of the end turns.

SPRINGS AND ELASTIC ELEMENTS n n n Coaxiality of springs with mating parts is achieved by installing support coils in special plates, bores in the body, grooves (see Fig. 4 c). Torsion springs (see Fig. 1 c) are usually wound with a small angle of rise and small gaps between the coils (0.5 mm). They perceive the external load with the help of hooks formed by the bending of the end turns.

SPRINGS AND ELASTIC ELEMENTS n n Basic parameters of coiled springs. Springs are characterized by the following main parameters (see Fig. 1b): wire diameter d or cross-sectional dimensions; average diameter Do, index c = Do/d; the number n of working turns; length Ho of the working part; step t = Ho/n turns, angle = arctg turns rise. The last three parameters are considered in the unloaded and loaded states.

SPRINGS AND ELASTIC ELEMENTS n n Basic parameters of coiled springs. Springs are characterized by the following main parameters (see Fig. 1b): wire diameter d or cross-sectional dimensions; average diameter Do, index c = Do/d; the number n of working turns; length Ho of the working part; step t = Ho/n turns, angle = arctg turns rise. The last three parameters are considered in the unloaded and loaded states.

SPRINGS AND ELASTIC ELEMENTS n n The spring index characterizes the curvature of the coil. Springs with an index of 3 are not recommended due to the high stress concentration in the coils. Usually, the spring index is chosen depending on the wire diameter as follows: for d 2.5 mm, d = 3--5; 6-12 mm respectively c = 5-12; 4-10; 4-9.

SPRINGS AND ELASTIC ELEMENTS n n The spring index characterizes the curvature of the coil. Springs with an index of 3 are not recommended due to the high stress concentration in the coils. Usually, the spring index is chosen depending on the wire diameter as follows: for d 2.5 mm, d = 3--5; 6-12 mm respectively c = 5-12; 4-10; 4-9.

SPRINGS AND ELASTIC ELEMENTS n n Materials. Coiled springs are made by cold or hot winding followed by end finishing, heat treatment and control. The main materials for springs are - high-strength special spring wire of 1, II and III classes with a diameter of 0.2-5 mm, as well as steels: high-carbon 65, 70; manganese 65 G; siliceous 60 C 2 A, chrome vanadium 50 HFA, etc.

SPRINGS AND ELASTIC ELEMENTS n n Materials. Coiled springs are made by cold or hot winding followed by end finishing, heat treatment and control. The main materials for springs are - high-strength special spring wire of 1, II and III classes with a diameter of 0.2-5 mm, as well as steels: high-carbon 65, 70; manganese 65 G; siliceous 60 C 2 A, chrome vanadium 50 HFA, etc.

SPRINGS AND ELASTIC ELEMENTS n n Springs designed to work in a chemically active environment are made of non-ferrous alloys. To protect the surfaces of the coils from oxidation, critical springs are varnished or oiled, and especially critical springs are oxidized and zinc or cadmium coated.

SPRINGS AND ELASTIC ELEMENTS n n Springs designed to work in a chemically active environment are made of non-ferrous alloys. To protect the surfaces of the coils from oxidation, critical springs are varnished or oiled, and especially critical springs are oxidized and zinc or cadmium coated.

SPRINGS AND ELASTIC ELEMENTS n n 2. Calculation and design of twisted cylindrical springs Stresses in sections and displacements of coils. Under the action of the axial force F (Fig. 5 a) in the cross section of the coil of the spring, the resulting inner strength F, parallel to the axis of the spring, and the moment T= F D 0/2, the plane of which coincides with the plane of the pair of forces F. The normal cross section of the coil is inclined to the plane of the moment at an angle.

SPRINGS AND ELASTIC ELEMENTS n n 2. Calculation and design of twisted cylindrical springs Stresses in sections and displacements of coils. Under the action of the axial force F (Fig. 5 a) in the cross section of the coil of the spring, the resulting inner strength F, parallel to the axis of the spring, and the moment T= F D 0/2, the plane of which coincides with the plane of the pair of forces F. The normal cross section of the coil is inclined to the plane of the moment at an angle.

SPRINGS AND ELASTIC ELEMENTS n n Projecting force factors in the cross section of a loaded spring on the x, y and z axes (Fig. 5, b), associated with the normal section of the coil, force F and moment T, we obtain Fx = F cos ; Fn = F sin (1) T = Mz = 0.5 F D 0 cos ; Mx = 0.5 F D 0 sin ;

SPRINGS AND ELASTIC ELEMENTS n n Projecting force factors in the cross section of a loaded spring on the x, y and z axes (Fig. 5, b), associated with the normal section of the coil, force F and moment T, we obtain Fx = F cos ; Fn = F sin (1) T = Mz = 0.5 F D 0 cos ; Mx = 0.5 F D 0 sin ;

SPRINGS AND ELEMENTS n n n The angle of elevation of the turns is small (usually 12). Therefore, we can assume that the cross section of the spring works on torsion, neglecting other force factors. In the section of the coil, the maximum shear stress is (2) where Wk is the moment of resistance to torsion of the coil section

SPRINGS AND ELEMENTS n n n The angle of elevation of the turns is small (usually 12). Therefore, we can assume that the cross section of the spring works on torsion, neglecting other force factors. In the section of the coil, the maximum shear stress is (2) where Wk is the moment of resistance to torsion of the coil section

SPRINGS AND ELASTIC ELEMENTS n Taking into account the curvature of the coils and relation (2), we write the equation (1), (3) n where F is the external load (tensile or compressive); D 0 - the average diameter of the spring; k - coefficient taking into account the curvature of the turns and the shape of the section (correction to the formula for torsion of a straight beam); k - allowable punitive stress during torsion.

SPRINGS AND ELASTIC ELEMENTS n Taking into account the curvature of the coils and relation (2), we write the equation (1), (3) n where F is the external load (tensile or compressive); D 0 - the average diameter of the spring; k - coefficient taking into account the curvature of the turns and the shape of the section (correction to the formula for torsion of a straight beam); k - allowable punitive stress during torsion.

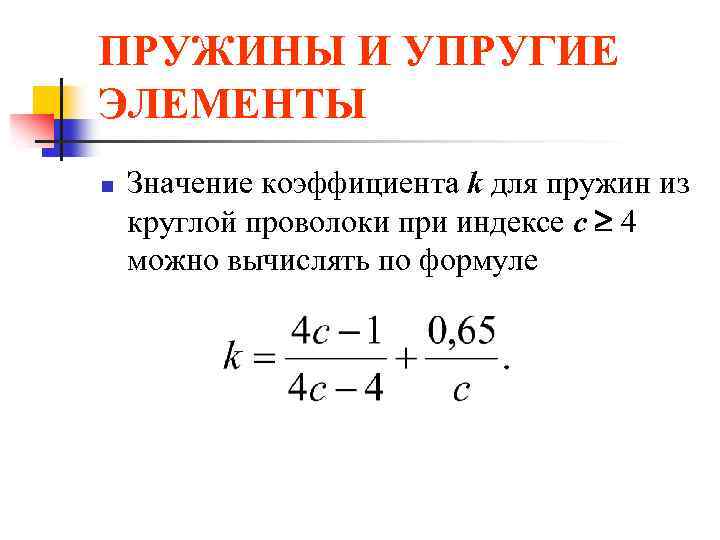

SPRINGS AND ELASTIC ELEMENTS n The value of the coefficient k for round wire springs with index c 4 can be calculated by the formula

SPRINGS AND ELASTIC ELEMENTS n The value of the coefficient k for round wire springs with index c 4 can be calculated by the formula

SPRINGS AND ELASTIC ELEMENTS n n If we take into account that for a wire of circular cross section Wk = d 3 / 16, then (4) A spring with a lift angle of 12 has an axial displacement n F, (5)

SPRINGS AND ELASTIC ELEMENTS n n If we take into account that for a wire of circular cross section Wk = d 3 / 16, then (4) A spring with a lift angle of 12 has an axial displacement n F, (5)

SPRINGS AND ELASTIC ELEMENTS n n where n is the coefficient of axial compliance of the spring. The compliance of a spring is most simply determined from energy considerations. Potential energy of the spring: where T is the torque in the cross section of the spring from the force F, G Jk is the torsional stiffness of the section of the coil (Jk 0, 1 d 4); l D 0 n is the total length of the working part of the coils;

SPRINGS AND ELASTIC ELEMENTS n n where n is the coefficient of axial compliance of the spring. The compliance of a spring is most simply determined from energy considerations. Potential energy of the spring: where T is the torque in the cross section of the spring from the force F, G Jk is the torsional stiffness of the section of the coil (Jk 0, 1 d 4); l D 0 n is the total length of the working part of the coils;

SPRINGS AND ELASTIC ELEMENTS n and coefficient of axial compliance of the spring (7) n where is the axial compliance of one coil (settlement in millimeters under the action of force F = 1 H),

SPRINGS AND ELASTIC ELEMENTS n and coefficient of axial compliance of the spring (7) n where is the axial compliance of one coil (settlement in millimeters under the action of force F = 1 H),

SPRINGS AND ELASTIC ELEMENTS n determined by the formula (8) n where G = E/ 0.384 E is the shear modulus (E is the modulus of elasticity of the spring material).

SPRINGS AND ELASTIC ELEMENTS n determined by the formula (8) n where G = E/ 0.384 E is the shear modulus (E is the modulus of elasticity of the spring material).

SPRINGS AND ELASTIC ELEMENTS n From formula (7) it follows that the coefficient of compliance of the spring increases with an increase in the number of turns (length of the spring), its index (outer diameter) and a decrease in the shear modulus of the material.

SPRINGS AND ELASTIC ELEMENTS n From formula (7) it follows that the coefficient of compliance of the spring increases with an increase in the number of turns (length of the spring), its index (outer diameter) and a decrease in the shear modulus of the material.

SPRINGS AND ELASTIC ELEMENTS n n Calculation and design of springs. The calculation of the wire diameter is carried out from the strength condition (4). For a given value of the index with (9) n where F 2 - the largest external load.

SPRINGS AND ELASTIC ELEMENTS n n Calculation and design of springs. The calculation of the wire diameter is carried out from the strength condition (4). For a given value of the index with (9) n where F 2 - the largest external load.

SPRINGS AND ELASTIC ELEMENTS n Permissible stresses [k] for springs made of steels 60 C 2, 60 C 2 H 2 A and 50 HFA take: 750 MPa - under the action of static or slowly changing variable loads, as well as for non-critical springs; 400 MPa - for responsible dynamically loaded springs. For dynamically loaded responsible springs made of bronze [k] assign (0, 2-0, 3) in; for irresponsible bronze springs - (0.4-0.6) c.

SPRINGS AND ELASTIC ELEMENTS n Permissible stresses [k] for springs made of steels 60 C 2, 60 C 2 H 2 A and 50 HFA take: 750 MPa - under the action of static or slowly changing variable loads, as well as for non-critical springs; 400 MPa - for responsible dynamically loaded springs. For dynamically loaded responsible springs made of bronze [k] assign (0, 2-0, 3) in; for irresponsible bronze springs - (0.4-0.6) c.

SPRINGS AND ELASTIC ELEMENTS n n The required number of working turns is determined from relation (5) according to the given elastic displacement (stroke) of the spring. If the compression spring is installed with a preliminary tightening (load) F 1, then (10) Depending on the purpose of the spring, the force F 1 = (0.1-0.5) F 2. By changing the value of F 1, you can adjust the working draft of the spring. The number of turns is rounded up to half a turn for n 20 and to one turn for n > 20.

SPRINGS AND ELASTIC ELEMENTS n n The required number of working turns is determined from relation (5) according to the given elastic displacement (stroke) of the spring. If the compression spring is installed with a preliminary tightening (load) F 1, then (10) Depending on the purpose of the spring, the force F 1 = (0.1-0.5) F 2. By changing the value of F 1, you can adjust the working draft of the spring. The number of turns is rounded up to half a turn for n 20 and to one turn for n > 20.

SPRINGS AND ELASTIC ELEMENTS n Total number of turns n n H 0 \u003d H 3 + n (t - d), (12) where H 3 \u003d (n 1 - 0, 5) d is the length of the spring, compressed until adjacent working turns come into contact; t is the step of the spring. n n n 1 = n + (l, 5 -2, 0). (11) An additional 1, 5-2 turns are used for compression to create bearing surfaces for the spring. On fig. 6 shows the relationship between load and compression spring settling. Full length of unloaded spring n

SPRINGS AND ELASTIC ELEMENTS n Total number of turns n n H 0 \u003d H 3 + n (t - d), (12) where H 3 \u003d (n 1 - 0, 5) d is the length of the spring, compressed until adjacent working turns come into contact; t is the step of the spring. n n n 1 = n + (l, 5 -2, 0). (11) An additional 1, 5-2 turns are used for compression to create bearing surfaces for the spring. On fig. 6 shows the relationship between load and compression spring settling. Full length of unloaded spring n

SPRINGS AND ELEMENTS n n The total number of turns is reduced by 0.5 due to the grinding of each end of the spring by 0.25 d to form a flat support end. The maximum spring settlement, i.e., the movement of the end of the spring until the coils are in full contact (see Fig. 6), is determined by the formula

SPRINGS AND ELEMENTS n n The total number of turns is reduced by 0.5 due to the grinding of each end of the spring by 0.25 d to form a flat support end. The maximum spring settlement, i.e., the movement of the end of the spring until the coils are in full contact (see Fig. 6), is determined by the formula

SPRINGS AND ELASTIC ELEMENTS n n n The pitch of the spring is determined depending on the value of 3 from the following approximate relationship: The length of the wire required for the manufacture of the spring where = 6 - 9° is the angle of elevation of the coils of an unloaded spring.

SPRINGS AND ELASTIC ELEMENTS n n n The pitch of the spring is determined depending on the value of 3 from the following approximate relationship: The length of the wire required for the manufacture of the spring where = 6 - 9° is the angle of elevation of the coils of an unloaded spring.

SPRINGS AND ELASTIC ELEMENTS n n To prevent spring buckling from loss of stability, its flexibility H 0 / D 0 must be less than 2.5. .

SPRINGS AND ELASTIC ELEMENTS n n To prevent spring buckling from loss of stability, its flexibility H 0 / D 0 must be less than 2.5. .

SPRINGS AND ELASTIC ELEMENTS n n n The installation length of the spring, i.e. the length of the spring after tightening it with force F 1 (see Fig. 6), is determined by the formula H 1 \u003d H 0 - 1 \u003d H 0 - n F 1 under the action of the largest external load spring length H 2 \u003d H 0 - 1 \u003d H 0 - n F 2 and the smallest length of the spring will be at force F 3 corresponding to the length H 3 \u003d H 0 - 3

SPRINGS AND ELASTIC ELEMENTS n n n The installation length of the spring, i.e. the length of the spring after tightening it with force F 1 (see Fig. 6), is determined by the formula H 1 \u003d H 0 - 1 \u003d H 0 - n F 1 under the action of the largest external load spring length H 2 \u003d H 0 - 1 \u003d H 0 - n F 2 and the smallest length of the spring will be at force F 3 corresponding to the length H 3 \u003d H 0 - 3

SPRINGS AND ELASTIC ELEMENTS n The angle of inclination of the straight line F = f() to the abscissa axis (see Fig. 6) is determined from the formula

SPRINGS AND ELASTIC ELEMENTS n The angle of inclination of the straight line F = f() to the abscissa axis (see Fig. 6) is determined from the formula

SPRINGS AND ELASTIC ELEMENTS n For heavy loads and cramped dimensions, compound compression springs are used (see Fig. 4, c) - a set of several (more often two) concentrically located springs that simultaneously perceive an external load. To prevent strong twisting of the end supports and distortions, the coaxial springs are wound in opposite directions (left and right). The supports are made in such a way that the mutual centering of the springs is ensured.

SPRINGS AND ELASTIC ELEMENTS n For heavy loads and cramped dimensions, compound compression springs are used (see Fig. 4, c) - a set of several (more often two) concentrically located springs that simultaneously perceive an external load. To prevent strong twisting of the end supports and distortions, the coaxial springs are wound in opposite directions (left and right). The supports are made in such a way that the mutual centering of the springs is ensured.

SPRINGS AND ELASTIC ELEMENTS n n For uniform distribution of the load between them, it is desirable that the composite springs have the same drafts (axial displacements), and the lengths of the springs, compressed until the coils touch, would be approximately the same. In the unloaded state, the length of the extension springs H 0 = n d+2 hz; where hz \u003d (0, 5- 1, 0) D 0 is the height of one hook. At maximum external load, the length of the extension spring H 2 \u003d H 0 + n (F 2 - F 1 *) where F 1 * is the force of the initial compression of the coils during winding.

SPRINGS AND ELASTIC ELEMENTS n n For uniform distribution of the load between them, it is desirable that the composite springs have the same drafts (axial displacements), and the lengths of the springs, compressed until the coils touch, would be approximately the same. In the unloaded state, the length of the extension springs H 0 = n d+2 hz; where hz \u003d (0, 5- 1, 0) D 0 is the height of one hook. At maximum external load, the length of the extension spring H 2 \u003d H 0 + n (F 2 - F 1 *) where F 1 * is the force of the initial compression of the coils during winding.

SPRINGS AND ELASTIC ELEMENTS n n The length of the wire for the manufacture of the spring is determined by the formula where lz is the length of the wire for one trailer.

SPRINGS AND ELASTIC ELEMENTS n n The length of the wire for the manufacture of the spring is determined by the formula where lz is the length of the wire for one trailer.

SPRINGS AND ELASTIC ELEMENTS n Springs are common, in which, instead of wire, a cable is used, twisted from two to six wires of small diameter (d = 0.8 - 2.0 mm), - stranded springs. By constructive solution such springs are equivalent to concentric springs. Due to their high damping capacity (due to friction between the strands) and compliance, stranded springs work well in shock absorbers and similar devices. Under the action of variable loads, stranded springs quickly fail due to wear of the cores.

SPRINGS AND ELASTIC ELEMENTS n Springs are common, in which, instead of wire, a cable is used, twisted from two to six wires of small diameter (d = 0.8 - 2.0 mm), - stranded springs. By constructive solution such springs are equivalent to concentric springs. Due to their high damping capacity (due to friction between the strands) and compliance, stranded springs work well in shock absorbers and similar devices. Under the action of variable loads, stranded springs quickly fail due to wear of the cores.

SPRINGS AND ELASTIC ELEMENTS n In structures operating under vibration and shock loads, shaped springs are sometimes used (see Fig. 1, d-f) with a nonlinear relationship between external force and elastic movement of the spring.

SPRINGS AND ELASTIC ELEMENTS n In structures operating under vibration and shock loads, shaped springs are sometimes used (see Fig. 1, d-f) with a nonlinear relationship between external force and elastic movement of the spring.

SPRINGS AND ELASTIC ELEMENTS n n Safety margins. Under the action of static loads, the springs can fail due to plastic deformations in the coils. In terms of plastic deformations, the margin of safety is where max is the largest shear stresses in the coil of the spring, calculated by formula (3), at F=F 1.

SPRINGS AND ELASTIC ELEMENTS n n Safety margins. Under the action of static loads, the springs can fail due to plastic deformations in the coils. In terms of plastic deformations, the margin of safety is where max is the largest shear stresses in the coil of the spring, calculated by formula (3), at F=F 1.

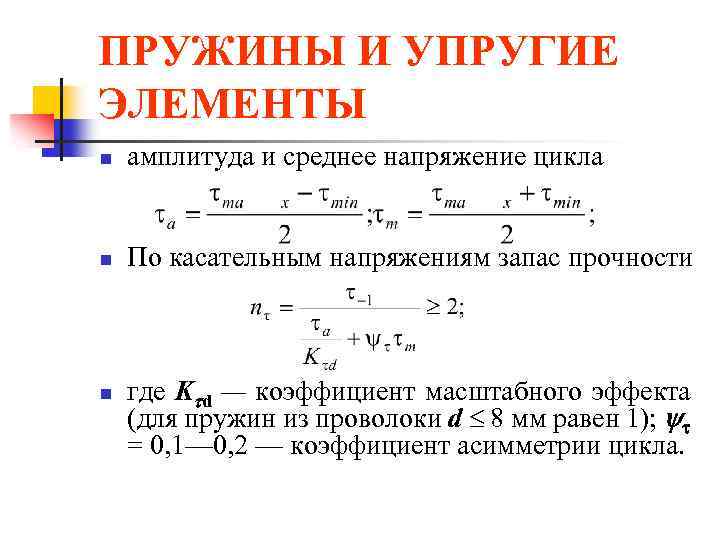

SPRINGS AND ELASTIC ELEMENTS n Springs operating continuously under variable loads must be designed for fatigue resistance. Springs are characterized by asymmetric loading, in which the forces change from F 1 to F 2 (see Fig. 6). At the same time, in the sections of the turns of the voltage

SPRINGS AND ELASTIC ELEMENTS n Springs operating continuously under variable loads must be designed for fatigue resistance. Springs are characterized by asymmetric loading, in which the forces change from F 1 to F 2 (see Fig. 6). At the same time, in the sections of the turns of the voltage

SPRINGS AND ELASTIC ELEMENTS n amplitude and average cycle stress n For tangential stresses safety margin n where K d is the scale effect coefficient (for springs made of wire d 8 mm is equal to 1); = 0, 1- 0, 2 - cycle asymmetry coefficient.

SPRINGS AND ELASTIC ELEMENTS n amplitude and average cycle stress n For tangential stresses safety margin n where K d is the scale effect coefficient (for springs made of wire d 8 mm is equal to 1); = 0, 1- 0, 2 - cycle asymmetry coefficient.

SPRINGS AND ELASTIC ELEMENTS n n Endurance limit - 1 wire with variable torsion in a symmetrical cycle: 300-350 MPa - for steels 65, 70, 55 GS, 65 G; 400-450 MPa - for steels 55 C 2, 60 C 2 A; 500-550 MPa - for steels 60 C 2 HFA, etc. When determining the safety factor, the effective stress concentration factor K = 1 is taken. The stress concentration is taken into account by the coefficient k in the formulas for stresses.

SPRINGS AND ELASTIC ELEMENTS n n Endurance limit - 1 wire with variable torsion in a symmetrical cycle: 300-350 MPa - for steels 65, 70, 55 GS, 65 G; 400-450 MPa - for steels 55 C 2, 60 C 2 A; 500-550 MPa - for steels 60 C 2 HFA, etc. When determining the safety factor, the effective stress concentration factor K = 1 is taken. The stress concentration is taken into account by the coefficient k in the formulas for stresses.

SPRINGS AND ELASTIC ELEMENTS n In the case of resonant vibrations of springs (for example, valve springs), an increase in the variable component of the cycle can occur with m unchanged. In this case, the margin of safety for alternating stresses

SPRINGS AND ELASTIC ELEMENTS n In the case of resonant vibrations of springs (for example, valve springs), an increase in the variable component of the cycle can occur with m unchanged. In this case, the margin of safety for alternating stresses

SPRINGS AND ELASTIC ELEMENTS n To increase fatigue resistance (by 20-50%), the springs are strengthened by shot-blasting, which creates compressive residual stresses in the surface layers of the coils. For processing springs, balls with a diameter of 0.5-1.0 mm are used. More efficient is the treatment of springs with balls of small diameters at high flight speeds.

SPRINGS AND ELASTIC ELEMENTS n To increase fatigue resistance (by 20-50%), the springs are strengthened by shot-blasting, which creates compressive residual stresses in the surface layers of the coils. For processing springs, balls with a diameter of 0.5-1.0 mm are used. More efficient is the treatment of springs with balls of small diameters at high flight speeds.

SPRINGS AND ELASTIC ELEMENTS n n Impact load calculation. In a number of designs (shock absorbers, etc.), springs operate under shock loads applied almost instantly (with high speed) with known impact energy. In this case, the individual coils of the spring gain considerable speed and can collide dangerously. The calculation of real systems for shock loading is associated with significant difficulties (taking into account contact, elastic and plastic deformations, wave processes, etc.); therefore, for an engineering application, we restrict ourselves to the energy calculation method.

SPRINGS AND ELASTIC ELEMENTS n n Impact load calculation. In a number of designs (shock absorbers, etc.), springs operate under shock loads applied almost instantly (with high speed) with known impact energy. In this case, the individual coils of the spring gain considerable speed and can collide dangerously. The calculation of real systems for shock loading is associated with significant difficulties (taking into account contact, elastic and plastic deformations, wave processes, etc.); therefore, for an engineering application, we restrict ourselves to the energy calculation method.

SPRINGS AND ELASTIC ELEMENTS n n n The main objective of impact load analysis is to determine dynamic settlement (axial displacement) and static load equivalent to impact on a spring with known dimensions. Consider the impact of a rod with mass m on a spring damper (Fig. 7). If we neglect the deformation of the piston and assume that after the impact, the elastic deformations instantly cover the entire spring, we can write the energy balance equation in the form where Fd is the force of gravity of the rod; K is the kinetic energy of the system after the collision,

SPRINGS AND ELASTIC ELEMENTS n n n The main objective of impact load analysis is to determine dynamic settlement (axial displacement) and static load equivalent to impact on a spring with known dimensions. Consider the impact of a rod with mass m on a spring damper (Fig. 7). If we neglect the deformation of the piston and assume that after the impact, the elastic deformations instantly cover the entire spring, we can write the energy balance equation in the form where Fd is the force of gravity of the rod; K is the kinetic energy of the system after the collision,

SPRINGS AND ELASTIC ELEMENTS n determined by the formula (13) n where v 0 - piston speed; - the coefficient of reduction of the mass of the spring to the place of impact

SPRINGS AND ELASTIC ELEMENTS n determined by the formula (13) n where v 0 - piston speed; - the coefficient of reduction of the mass of the spring to the place of impact

SPRINGS AND ELASTIC ELEMENTS n n n If we assume that the speed of movement of the coils of the spring changes linearly along its length, then = 1/3. The second term on the left side of equation (13) expresses the work of the piston after impact with dynamic spring settlement q. The right side of equation (13) is the potential energy of deformation of the spring (with compliance m), which can be returned by gradually unloading the deformed spring.

SPRINGS AND ELASTIC ELEMENTS n n n If we assume that the speed of movement of the coils of the spring changes linearly along its length, then = 1/3. The second term on the left side of equation (13) expresses the work of the piston after impact with dynamic spring settlement q. The right side of equation (13) is the potential energy of deformation of the spring (with compliance m), which can be returned by gradually unloading the deformed spring.

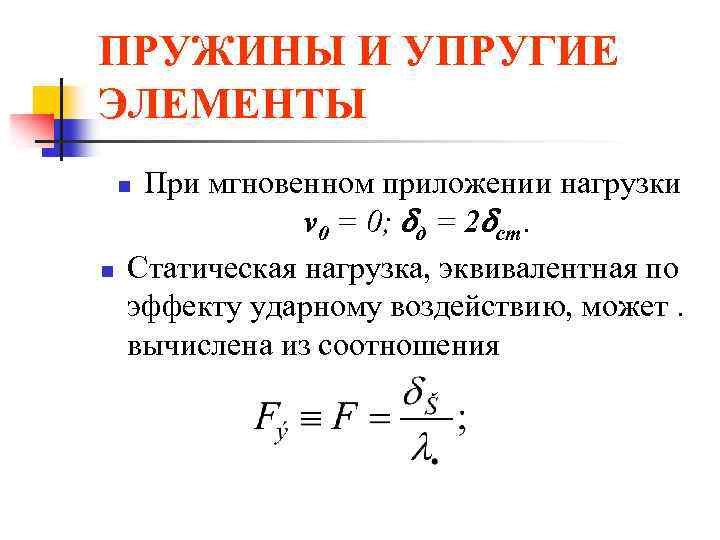

SPRINGS AND ELASTIC ELEMENTS With an instantaneous load v 0 = 0; d \u003d 2 tbsp. A static load equivalent in effect to an impact can. calculated from the relation n n

SPRINGS AND ELASTIC ELEMENTS With an instantaneous load v 0 = 0; d \u003d 2 tbsp. A static load equivalent in effect to an impact can. calculated from the relation n n

SPRINGS AND ELASTIC ELEMENTS n n Rubber elastic elements are used in the construction of elastic couplings, vibration and noise insulating supports and other devices to obtain large displacements. Such elements usually transfer the load through metal parts (plates, tubes, etc.).

SPRINGS AND ELASTIC ELEMENTS n n Rubber elastic elements are used in the construction of elastic couplings, vibration and noise insulating supports and other devices to obtain large displacements. Such elements usually transfer the load through metal parts (plates, tubes, etc.).

SPRINGS AND ELASTIC ELEMENTS n Advantages of rubber elastic elements: electrical insulating ability; high damping capacity (energy dissipation in rubber reaches 30-80%); ability to accumulate large quantity energy per unit mass than spring steel (up to 10 times). In table. 1 shows calculation schemes and formulas for the approximate determination of stresses and displacements for rubber elastic elements.

SPRINGS AND ELASTIC ELEMENTS n Advantages of rubber elastic elements: electrical insulating ability; high damping capacity (energy dissipation in rubber reaches 30-80%); ability to accumulate large quantity energy per unit mass than spring steel (up to 10 times). In table. 1 shows calculation schemes and formulas for the approximate determination of stresses and displacements for rubber elastic elements.

SPRINGS AND ELASTIC ELEMENTS n n The material of the elements is technical rubber with a tensile strength (in 8 MPa; shear modulus G = 500-900 MPa. V last years pneumoelastic elastic elements become widespread.

SPRINGS AND ELASTIC ELEMENTS n n The material of the elements is technical rubber with a tensile strength (in 8 MPa; shear modulus G = 500-900 MPa. V last years pneumoelastic elastic elements become widespread.

Definition

The force that occurs as a result of the deformation of the body and trying to return it to its original state is called elastic force.

Most often it is denoted by $(\overline(F))_(upr)$. The elastic force appears only when the body is deformed and disappears if the deformation disappears. If, after removing the external load, the body completely restores its size and shape, then such a deformation is called elastic.

R. Hooke, a contemporary of I. Newton, established the dependence of the elastic force on the magnitude of the deformation. Hooke doubted the validity of his conclusions for a long time. In one of his books, he gave an encrypted formulation of his law. Which meant: "Ut tensio, sic vis" in Latin: what is the stretch, such is the strength.

Consider a spring subject to a tensile force ($\overline(F)$) that is directed vertically downwards (Fig. 1).

The force $\overline(F\ )$ is called the deforming force. Under the influence of a deforming force, the length of the spring increases. As a result, an elastic force ($(\overline(F))_u$) appears in the spring, balancing the force $\overline(F\ )$. If the deformation is small and elastic, then the elongation of the spring ($\Delta l$) is directly proportional to the deforming force:

\[\overline(F)=k\Delta l\left(1\right),\]

where in the coefficient of proportionality is called the stiffness of the spring (coefficient of elasticity) $k$.

Rigidity (as a property) is a characteristic of the elastic properties of a body that is being deformed. Rigidity is considered the body's ability to resist external force, the ability to save their geometric parameters. The greater the stiffness of the spring, the less it changes its length under the influence of a given force. The stiffness coefficient is the main characteristic of stiffness (as a property of a body).

The coefficient of spring stiffness depends on the material from which the spring is made and its geometric characteristics. For example, the stiffness coefficient of a coiled coil spring, which is wound from round wire and subjected to elastic deformation along its axis, can be calculated as:

where $G$ is the shear modulus (value depending on the material); $d$ - wire diameter; $d_p$ - spring coil diameter; $n$ is the number of coils of the spring.

The unit of measure for the stiffness coefficient in international system units (SI) is the newton divided by the meter:

\[\left=\left[\frac(F_(upr\ ))(x)\right]=\frac(\left)(\left)=\frac(H)(m).\]

The stiffness coefficient is equal to the amount of force that must be applied to the spring to change its length per unit distance.

Spring stiffness formula

Let $N$ springs be connected in series. Then the stiffness of the entire joint is equal to:

\[\frac(1)(k)=\frac(1)(k_1)+\frac(1)(k_2)+\dots =\sum\limits^N_(\ i=1)(\frac(1) (k_i)\left(3\right),)\]

where $k_i$ is the stiffness of the $i-th$ spring.

When the springs are connected in series, the stiffness of the system is determined as:

Examples of problems with a solution

Example 1

Exercise. The spring in the absence of load has a length $l=0.01$ m and a stiffness equal to 10 $\frac(N)(m).\ $What will be the stiffness of the spring and its length if the force acting on the spring is $F$= 2 N ? Assume that the deformation of the spring is small and elastic.

Solution. The stiffness of the spring under elastic deformations is a constant value, which means that in our problem:

Under elastic deformations, Hooke's law is fulfilled:

From (1.2) we find the elongation of the spring:

\[\Delta l=\frac(F)(k)\left(1.3\right).\]

The length of the stretched spring is:

Calculate the new length of the spring:

Answer. 1) $k"=10\ \frac(Н)(m)$; 2) $l"=0.21$ m

Example 2

Exercise. Two springs with stiffnesses $k_1$ and $k_2$ are connected in series. What will be the elongation of the first spring (Fig. 3) if the length of the second spring is increased by $\Delta l_2$?

Solution. If the springs are connected in series, then the deforming force ($\overline(F)$) acting on each of the springs is the same, that is, it can be written for the first spring:

For the second spring we write:

If the left parts of expressions (2.1) and (2.2) are equal, then the right parts can also be equated:

From equality (2.3) we obtain the elongation of the first spring:

\[\Delta l_1=\frac(k_2\Delta l_2)(k_1).\]

Answer.$\Delta l_1=\frac(k_2\Delta l_2)(k_1)$